| A345 US TYPE MASTER LINK ASSEMBLY | ||||||||||||

| Size(mm) | Weight (KG) | American chain | 3 or 4 chain marking working load (The Angle 0-45°) |

Rope working load(T) |

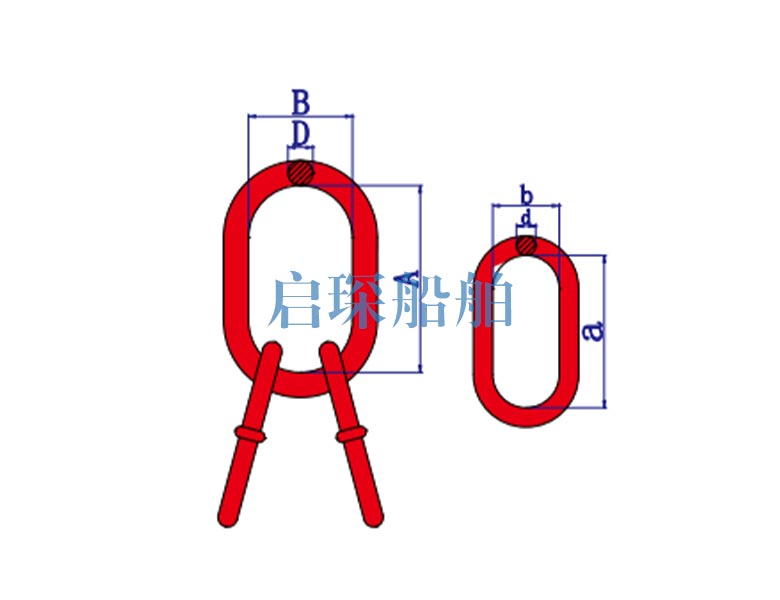

A | B | D | a | b | d | Regular Marking | Production Way |

| 3/4 | 1.70 | 1/4 | 3.15 | 5.6 | 140±6 | 70±5 | 20±1 | 85±5 | 40±3 | 14±1 | WLL4.25T | 母环锻造 子环焊接 |

| 5/16 | 4.25 | |||||||||||

| 7/8 | 2.18 | 5/16 | 4.25 | 6.9 | 160±6 | 95±5 | 22±1 | 85±5 | 40±5 | 14±1 | WLL6.7T | 母环锻造 子环焊接 |

| 3/8 | 6.7 | |||||||||||

| 1 | 3.29 | 3/8 | 6.7 | 11.8 | 178±6 | 89±5 | 25±1 | 100±5 | 60±5 | 18±1 | WLL6.7T | 母环锻造 子环焊接 |

| 11/4 | 7.18 | 1/2 | 11.2 | 17.7 | 220±7 | 110±6 | 32+1-2 | 100±5 | 60±5 | 22±1 | WLL17T | 母环锻造 子环焊接 |

| 5/8 | 17 | |||||||||||

| 11/2 | 12.91 | 5/8 | 17 | 27.7 | 267±7 | 135±6 | 38+1-2 | 180±6 | 100±5 | 30+1-2 | WLL23.6T | 母环锻造 子环焊接 |

| 3/4 | 23.6 | |||||||||||

| 13/4 | 21.25 | 3/4 | 23.6 | 38.5 | 305±10 | 152±6 | 45+1-2 | 180±6 | 100±5 | 32+1-2 | WLL31.5T | 母环锻造 子环焊接 |

| 7/8 | 31.5 | |||||||||||

| 2 | 30.34 | 7/8 | 31.5 | 46.5 | 356±10 | 178±6 | 50+1-2 | 180±6 | 100±5 | 38+1-2 | WLL31.5T | 母环锻造 子环焊接 |

| 21/2 | 64.40 | 1 | 45 | 72.6 | 406±10 | 203±6 | 64+1-2 | 355±8 | 178±6 | 51+1-2 | WLL45T | 母环锻造 子环焊接 |

| 23/4 | 89.00 | 11/4 | 67 | 98.4 | 406±10 | 241±6 | 70+1-2 | 406±8 | 203±6 | 57+1-2 | WLL67T | 母环锻造 子环焊接 |

● Material: Forged super alloy steel

● 100% tested at 2.5 times Working Load Limit

● 100% magnaflux crack detection

● Breakage test

● For Chain sling:Minimum Ultimate Load is 4 times the Working Load Limit

● For steel rope sling:Minimum Ultimate Load is 5 times the Working Load Limit

● The pressing flat for use with G80 OMEGA LINK (Stock No GS502)

● There will be pressing flat only on request

CN

CN EN

EN

Your location:

Your location:

Home

Home Tel

Tel Product

Product